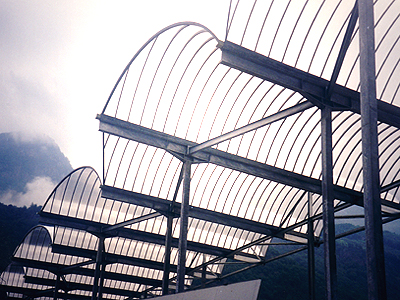

Sun Modul Curvo, for arches applications

Sun Modul Curvo, for arches applications

SUN MODUL, the self-supporting system, is presented here in its curved application. Whether it is for skylights for industrial, agricultural and public buildings (stadiums, gymnasiums, swimming pools, tennis courts, etc ...) or translucent arches (passages, shelters, tunnels, washing stations, etc.) SUN MODUL CURVO is the solution ideal. The polycarbonate assembly with multi-wall honeycomb structure, with a patented connection, consisting of self-supporting steel studs and anti-skid polycarbonate covers, gives this system outstanding characteristics in the area of curved covers.

Sun Modul Curvo panels

SUN MODUL CURVO panels are manufactured by extrusion based on virgin polycarbonate. They have optimum brightness and, thanks to the component raw material, are practically unbreakable. The stability and durability of SUN MODUL CURVO panels over time, including resistance to atmospheric agents, are ensured by a special high-tech anti-UV treatment.Available colors: colorless and, on request, white diffusing and smoked bronze.

The modular width of the SUN MODUL CURVO system is 500mm. This modularity is aesthetically highlighted by the polycarbonate anti-creeping hoods that ensure exceptional overall performance.

The alveolar structure gives the SUN MODUL CURVO panels a high rigidity as well as an excellent thermo-insulating property:

Thick. 10mm - 3 walls - K = 2.7 W / m²K

Thick. 16mm - 4 walls - K = 2.2 W / m²K

Due to the minimum radius of 2000mm for the 10mm thickness and 4500mm for the 16mm thickness, the SUN MODUL CURVO panels are perfectly adapted to all curved shapes. The SUN MODUL CURVO ep. 10mm are classified M2 (PV 6602-95 SNPE).

SUN MODUL CURVO panels are lightweight and extremely easy to install (see installation diagram).

Steel uprights and polycarbonate cowls

The steel uprights, by their adapted shape, enable the frontal installation of the SUN MODUL CURVO panels by interlocking, which makes the assembly of the system very simple. The thickness and the geometry of the steel uprights guarantee a high rigidity, allowing a very high free range. The posts are bent at the factory according to the radius requested.

The assembly, steel uprights and polycarbonate cowls anti-unclip, ensures a perfect watertightness. The steel uprights, set back from the SUN MODUL CURVO panels, avoid any thermal bridging. They are galvanized and plasticized, ensuring both aesthetics and durability. The mounting of the steel uprights can be done after fitting the SUN MODUL CURVO panels, thus saving a lot of time for installation.

The UV-treated polycarbonate cowls are mounted successively after fitting the panels and guarantee an anti-unclip system.

The cowl appearance gives the whole system the impression of a continuous surface.

Framing

The uprights are normally fixed on laterally folded sheets (to be provided by the installer).

Special alloy profiles make it possible to produce eardrums.

PE seals ensure air tightness.