Main brands : Plexiglas®, Altuglas®

Certainly the most aesthetic thermoplastic because of its perfect transparency and its numerous finishes and hues that make it a pleasant product for the eye and to touch. But it is also a material that finds its place in the industrial world; its declinations range allows it to fulfill many functions.

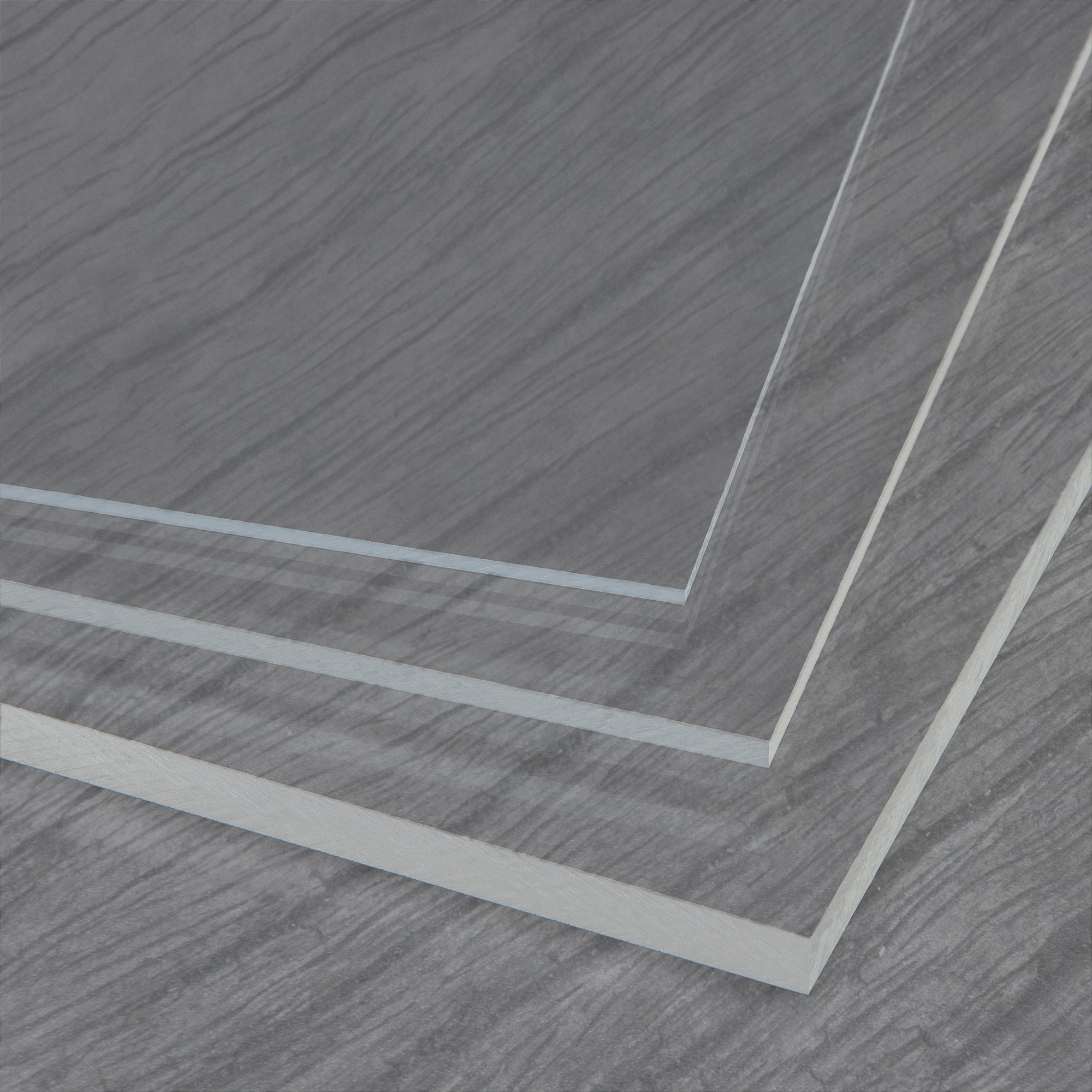

PMMA exists in two main forms depending on the manufacturing method: cast or extruded.

CAST ACRYLIC SHEETS (PMMA GS or CN)

The cast PMMA, thanks to an excellent resistance to UV rays, keeps indefinitely its mechanical properties and transparency. The PMMA is colorless with a light transmission greater than the glass and equal to the crystal. The cast plates do not opacify and retain their initial appearance. Cast PMMA is available in a wide variety of thicknesses.

Protection

The cast PMMA sheets are systematically protected on both sides by a polyethylene film.

Dimensions tolerance

Standard sizes: - 0 mm to + 10 mm. Formats cut: ± 1 mm / ml, with a minimum tolerance of ± 1 mm.

Blocks

The standard one-piece production is standard up to 200 mm thick. For thicknesses greater than 90 mm, delivery is made "raw manufacturing surface", nominal thickness guaranteed.Cutting tolerance: - 0 mm to + 10 mm.

Reference face or "visible face"

The reference face of the products is the one whose the protective film bears the commercial marking.

Color specifications

PMMA is by nature a transparent material, it can not in any case, even in its most heavily loaded formulations, be assimilated to an opaque material.

There may be slight differences in color from one production to another, caused by fluctuations inherent in batches of dyes.

Dyes manufacturers do not guarantee the resistance of their colors over time; nevertheless, in the majority of cases, the dress is level 7 according to the blue scale of the International Standard ISO 105.

Weight of cast PMMA sheets

The density of the cast PMMA sheets is 1.19. The sheet weight is obtained by multiplying the area in m², by the thickness in mm, then by 1.19.

Warranty

Cast PMMA sheets of all thicknesses up to 25 mm retain their characteristics practically intact for 10 years of exposure to the outside.

Dimensions and thickness

CAST SHEETS

| THICKNESS (mm) | SIZE (m) |

| 2 ; 3 ; 4 ; 5 ; 6 ; 8 ; 10 ; 12 ; 15 ; 20 ; 25 | 3050 x 2030 |

| 30 ; 40 ; 50 ; 60 ; 70 ; 80 ; 90 ; 100 ; 110 ; 120 ; 150 | 3000 x 2000 |

Standard color: colorless

Other existing colors: white, smoked. (+ many colors usually in thickness 3 mm)

Available in version: diffusing light, quality shock, mirror, satin, granite, structured, untreated anti-UV, granite, anti-reflective coating

CAST RODS

| DIAMETER (mm) | LENGTH (m) |

| 2 ; 3 ; 4 ; 5 ; 6 ; 7 ; 8 ; 9 ; 10 ; 11 ; 12 ; 13 ; 14 ; 15 ; 16 ; 18 ; 20 ; 22 ; 25 ; 28 ; 30 ; 35 ; 40 ; 45 ; 50 ; 55 | 2000 |

| 60 ; 70 ; 75 ; 80 ; 85 ; 90 ; 95 ; 100 ; 110 ; 115 ; 120 ; 130 ; 140 ; 150 ; 160 ; 180 ; 200 ; 250 | 1000 |

Standard color: colorless

Other existing colors: white. (+ many colors)

Available in version: diffusing light, satin, fluorescent

EXTRUDED ACRYLIC SHEETS (PMMA XT)

The extruded sheets are produced from Polymethyl Methacrylate. They are extruded and calendered, which gives them an excellent and constant thickness tolerancy. They are remarkably thermoformable.

Protection

The cast PMMA shhets are systematically protected on both sides by a polyethylene film.

Dimensions tolerance

Standard or cut-out formats: - 0 mm to + 10 mm. For thicknesses of less than 2 mm, the manufacturing formats may have a rough extrusion border.

Formats cut: ± 1 mm / ml, with a minimum tolerance of ± 1 mm.

For special tolerances, consult the sales department.

Color Specifications

The hue and light transmission are derived from a reference thickness, so they vary according to the thickness.

Weight of extruded PMMA sheets

The density of the extruded PMMA is 1.19. The sheet weight is obtained by multiplying the area in m², by the thickness in mm, then by 1.19.

Storage

In case of extended storage it is strongly recommended to pack the pallet under a polyethylene envelope in order to slow down the moisture recovery phenomena.

Warranty

Extruded PMMA sheets retain their characteristics for almost 10 years intact, for any thickness.

Dimensions and thickness

EXTRUDED SHEETS

| THICKNESS (mm) | SIZE (m) |

| 2 ; 3 ; 4 ; 5 ; 6 ; 8 ; 10 ; 12 ; 15 ; 20 ; 25 | 3050 X 2050 |

Standard color: colorless

Other existing colors: white, smoked, (+ many colors generally in thickness 3 mm)

Available in version: diffusing light, shock quality

EXTRUDED TUBES

|

DIAMETER (mm) |

LENGTH (mm) |

|

|

8 x 4 |

60 x 50 |

2000 |

|

10 x 6 |

60 x 52 |

|

|

10 x 7 |

60 x 54 |

|

|

12 x 6 |

60 x 56 |

|

|

12 x 8 |

70 x 60 |

|

|

12 x 10 |

70 x 62 |

|

|

13 x 9 |

70 x 64 |

|

|

13 x 10 |

70 x 66 |

|

|

14 x 10 |

80 x 70 |

|

|

15 x 11 |

80 x 72 |

|

|

16 x 12 |

80 x 74 |

|

|

18 x 14 |

90 x 80 |

|

|

20 x 14 |

90 x 82 |

|

|

20 x 16 |

90 x 84 |

|

|

24 x 20 |

100 x 90 |

|

|

25 x 19 |

100 x 92 |

|

|

25 x 21 |

100 x 94 |

|

|

26 x 20 |

110 x 100 |

|

|

30 x 20 |

110 x 104 |

|

|

30 x 22 |

120 x 110 |

|

|

30 x 24 |

120 x 114 |

|

|

30 x 26 |

150 x 140 |

|

|

34 x 30 |

150 x 142 |

|

|

36 x 30 |

150 x 144 |

|

|

38 x 32 |

180 x 172 |

|

|

40 x 30 |

180 x 174 |

|

|

40 x 32 |

200 x 190 |

|

|

40 x 34 |

200 x 192 |

|

|

40 x 36 |

200 x 194 |

|

|

50 x 40 |

250 x 240 |

|

|

50 x 42 |

250 x 242 |

|

|

50 x 44 |

250 x 244 |

|

|

50 x 46 |

|

|

For other diameters please contact us - Some diameters are subject to a minimum order, contact the sales department

Standard color: colorless

Other existing colors: white, smoked

Available in version: diffusing light